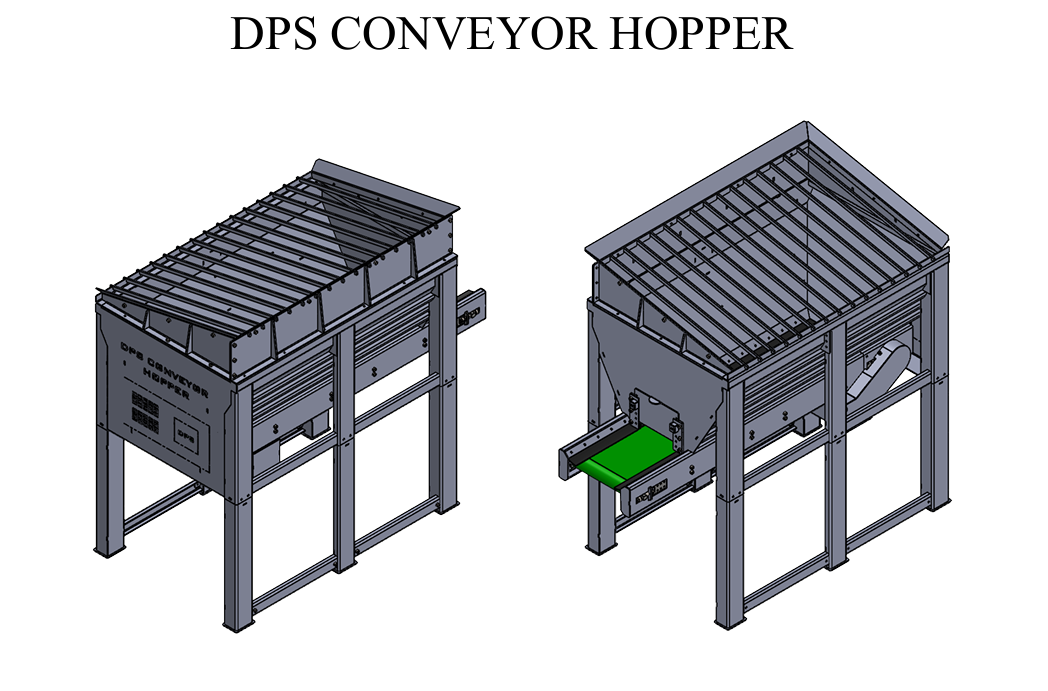

DPS-CONVEYOR HOPPER 2025

1. Function:

The Conveyor Hopper is designed to receive, hold, and transport materials either continuously or in measured amounts through a conveyor system.

2. Construction Material:

Frame and body:

Made from high-grade stainless steel (inox) or powder-coated steel, depending on the application.

Stainless steel offers excellent corrosion resistance and easy cleaning—ideal for food and medical industries.

Powder-coated steel enhances durability, aesthetics, and oxidation resistance—suitable for industrial environments.

3. Drive System:

Geared motor:

Uses a high-efficiency DC geared motor operating at 12V–24V, ensuring stable and quiet performance.

Allows adjustable conveyor speed to meet operational needs.

Energy-efficient and long-lasting.

Belt & pulley transmission system:

Motion is transferred from the motor to the conveyor shaft via belt and pulley system.

Designed for safe, quiet, and smooth operation; easy to maintain and replace components.

4. Industrial Conveyor Belt:

Conveyor belt material: High-durability industrial rubber or PVC/PU with excellent wear resistance.

Roller system: Supports smooth and stable belt movement, minimizing misalignment.

5. Advantages:

High durability, designed for continuous operation in industrial settings.

Compact design, easy to integrate into automation lines.

Low maintenance, user-friendly operation.

Customizable: Hopper height, belt length, and motor speed can be tailored to specific requirements.

DPS-CONVEYOR HOPPER 2025

1. Function:

The Conveyor Hopper is designed to receive, hold, and transport materials either continuously or in measured amounts through a conveyor system.

2. Construction Material:

Frame and body:

Made from high-grade stainless steel (inox) or powder-coated steel, depending on the application.

Stainless steel offers excellent corrosion resistance and easy cleaning—ideal for food and medical industries.

Powder-coated steel enhances durability, aesthetics, and oxidation resistance—suitable for industrial environments.

3. Drive System:

Geared motor:

Uses a high-efficiency DC geared motor operating at 12V–24V, ensuring stable and quiet performance.

Allows adjustable conveyor speed to meet operational needs.

Energy-efficient and long-lasting.

Belt & pulley transmission system:

Motion is transferred from the motor to the conveyor shaft via belt and pulley system.

Designed for safe, quiet, and smooth operation; easy to maintain and replace components.

4. Industrial Conveyor Belt:

Conveyor belt material: High-durability industrial rubber or PVC/PU with excellent wear resistance.

Roller system: Supports smooth and stable belt movement, minimizing misalignment.

5. Advantages:

High durability, designed for continuous operation in industrial settings.

Compact design, easy to integrate into automation lines.

Low maintenance, user-friendly operation.

Customizable: Hopper height, belt length, and motor speed can be tailored to specific requirements.